Cx Designer Software Download

. The network status diagnosis results show the status of the specified Controller Link network (transmission path type, baud rate, communications cycle time, data link status (automatic/manual, active), polling node, and starting node) and the status of the nodes participating in the specified Controller Link network (participating in data links, errors, names, etc.).Any differences between the nodes registered in the specified node file and the actual nodes will be displayed.

The operating status of the CPU Units and Controller Link Units/Boards is checked. Error information will be displayed if any errors occur. The operation of networks with configurations consisting of multiple networks including PLC networks such as EtherNet/IP™ and Controller Link, field networks such as DeviceNet™ and CompoNet™, and networks for Programmable Terminals and Serial Devices, can be restored simultaneously from the CX-One. Onsite start up and debugging can be conducted efficiently and without errors because PLCs and devices can be selected from the window to transfer programs and parameter data to the computer during operation.Ladder Diagram Monitoring for Multiple PLCs. Functionality and operability has been significantly upgraded compared to the previous data trace function.

Cx Designer Program

The new data trace function provides comprehensive debugging, such as I/O comment display of sampled addresses, specification using symbols, checking the measurement time between two selected points, and layering waveforms. Furthermore, data sampled from the CPU Unit's trace memory can be saved to a file on the computer at a specified frequency.

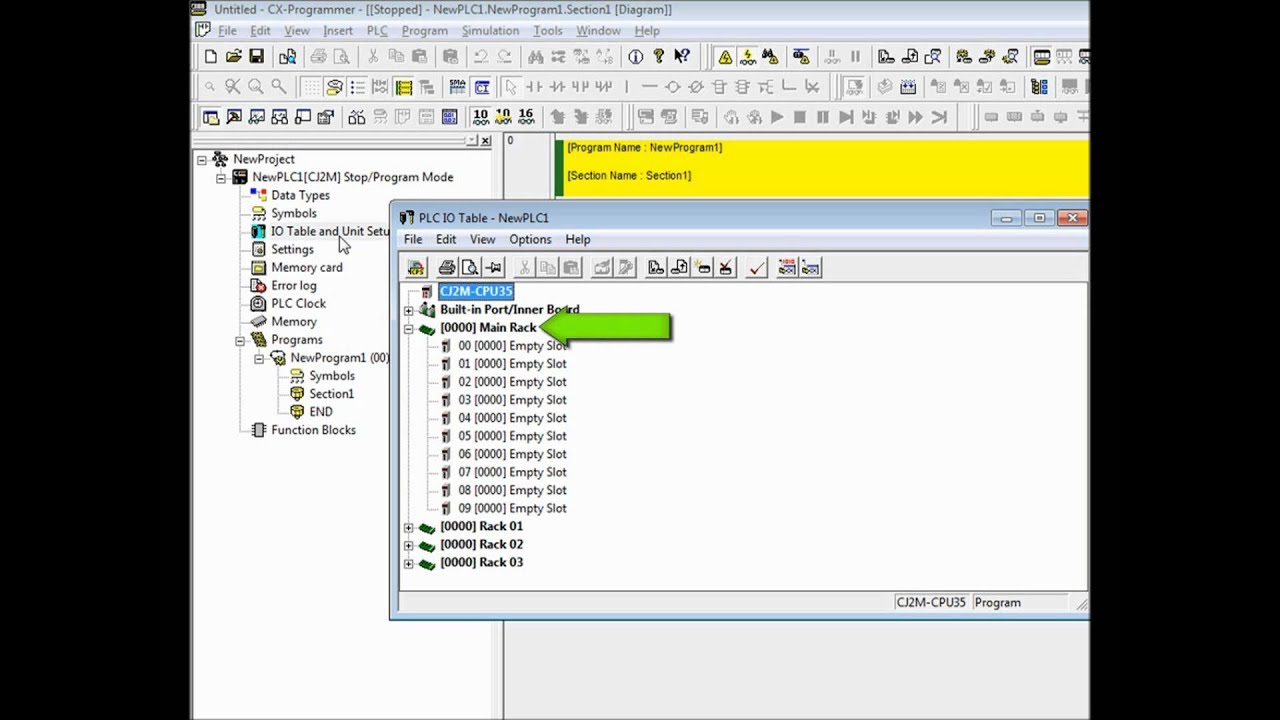

This can be used as for long-term logging of data.Data Trace Function. Test functions for the CX-Designer and CX-Programmer are linked through the CX-Simulator on a computer. This enables screens and ladder diagrams to be checked simultaneously, significantly improving the debugging efficiency. A new Integrated Simulation Button has been added to the CX-Programmer.Furthermore, work efficiency has been significantly improved with the function that enables work windows to be pinned in front, and a flexible zoom function.Screens and Ladder Diagrams Can Be Simultaneously Checked on a Computer. The execution of the autotuning (AT) function that calculates the PID constants and the fine tuning (FT) function that improves controllability exactly as required are made easy with an intuitive user interface.

The interference overshooting adjustment function is supported to adjust overshooting when interference occurs, and the gradient temperature control function achieves constant internal temperatures for multi-point temperature control with interference.Note: Supported functions depends on the product being used. Refer to product manuals for details. Easy to Use without Any Technical Knowledge. Provides software components that help you easily and quickly develop PLC communications. Read and write PLC data without the need to consider differences between networks. Supports Microsoft Visual Studio 2015.

For the CJ2 (with EtherNet/IP functionality) or NJ/NX/NY, I/O memory in the PLC can be accessed by using tag names rather than addresses. Array and structure variable access is possible.Communications Middleware to Connect a Computer and PLCs SYSMAC Gateway.